Solaris® Hydroheater

Solaris® Hydroheater

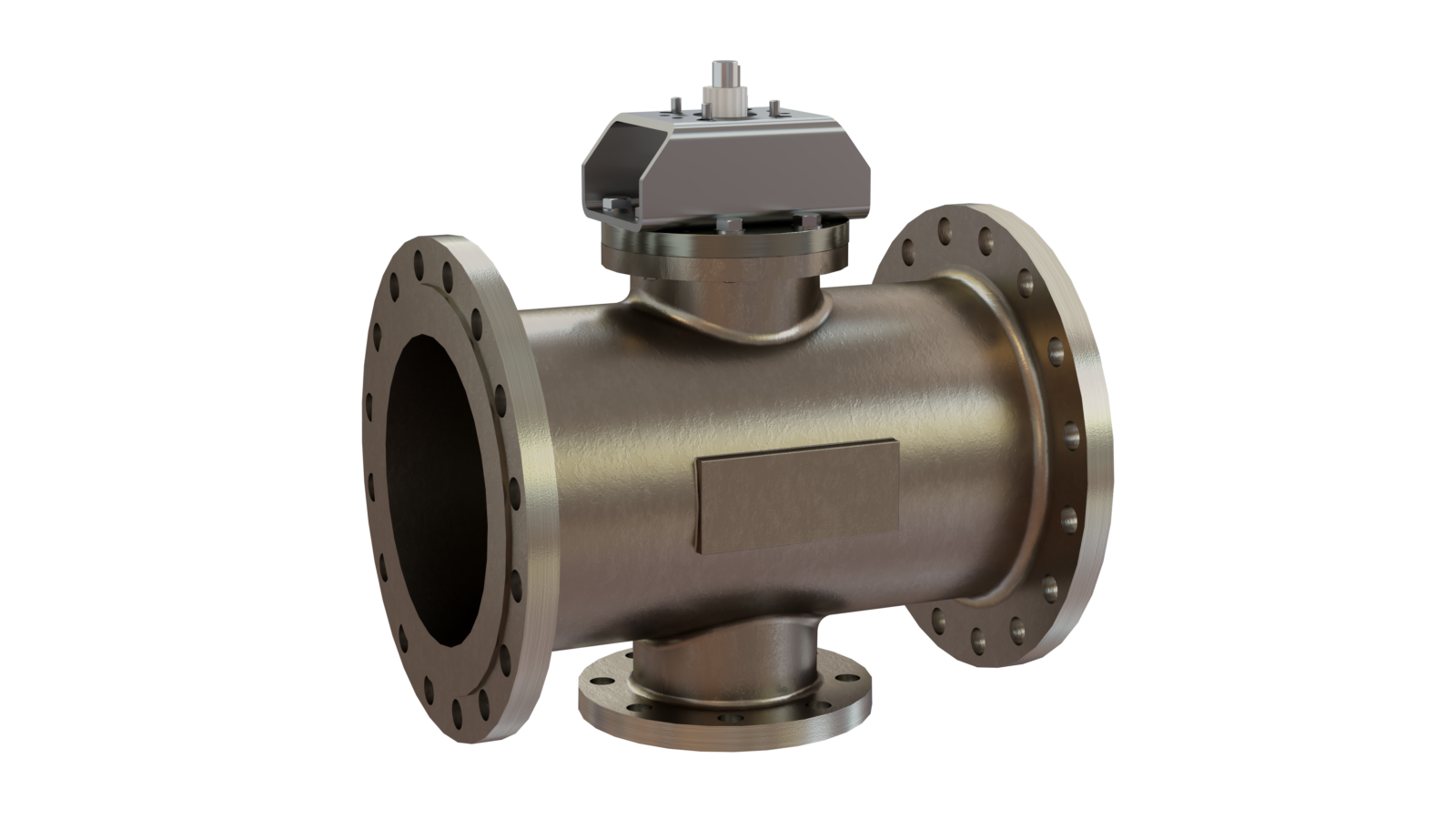

The Solaris® features a Cross-Flow Diffuser that injects steam across the entire cross-section of flow to ensure thorough mixing and a uniform temperature profile. It utilizes low shear flow, making it ideal for slurries with high solid contents and process fluids where chunk size must be maintained.

Pressure & Temperature

- Max Pressure – 300 PSIG / 20.7 Barg

- Max Temperature – 450°F / 232°C

Flow Turndown

- Up to 10:1 Liquid Turndown

Connection Types

- ANSI Class 150 & Class 300

- DIN PN16, PN25, PN40

- Straight-Through design delivers uniform heating and mixing without plugging

- Patented Cross-Flow Diffuser uniformly distributes the heat into the liquid

- Rotating Stem Plug meters and regulates steam flow

- Instantaneous condensation of steam eliminates hammer and vibration

- Multiple heater sizes to meet your process needs

- Precise temperature control +/-1°F [.50°C]

- Straight through design

- Low pressure drop compared to other steam injection technology

- Ensures thorough mixing and uniform temperature profile

- Low shear, maintains particle size

- Directly integrates into existing plant utilities

- Available as a standalone heater or skidded system

- Multiple heater sizes to meet your process needs

- Stainless steel cast construction designed to withstand the most severe applications; other custom materials available

- Sludge Heating

- Pulp Stock Heating

- Back Set Heating

- Bleaching

- Viscous/High Solid/Fibrous Slurries

- Aseptic Applications (Tomato Paste)

- Corn Oil

- General Water Heating

- Food

- Wastewater

- Chemical

- Pharmaceuticals (Personal Care & Bio Tech

- Energy & Utilities (Oil & Gas)

- Paper & Pulp

- Renewable Fuel (Ethanol)

Other

- Mining (Processing Facilities)

- Metal

- Automotive

Sizing & Process Parameters

S203 | S204 | S206 | S208 | S210 | S212 | |

Steam Inlet | 2.5 in. / 64.0 mm. | 2.5 in. / 64.0 mm. | 4.0 in. / 102.0 mm. | 4.0 in. / 102.2 mm. | 6.0 in. / 152.4 mm. | 6.0 in. / 152.4mm. |

Process Inlet | 3.0 in. / 76.2 mm. | 4.0 in. / 102,0 mm. | 6.0 in. / 152.4 mm. | 8.0 in. / 203.2 mm. | 10.0 in. / 203.2 mm. | 12.0 in. / 304.8 mm. |

Process Outlet | 3.0 in. / 76.2 mm. | 4.0 in. / 120.0 mm. | 6.0 in. / 152.4 mm. | 8.0 in. / 203.2 mm. | 10.0 in. / 203.3 mm. | 12.0 in. / 304.8 mm. |

Min. Flow (GPM/m3/hr) | 105 / 47 | 134 / 61 | 235 / 106 | 287 / 130 | 346 / 157 | 519 / 235 |

Max. Flow (GPM/m3/hr) | 105 / 47 | 600 / 146 | 1,300 / 296 | 2,200 / 500 | 3,700 / 840 | 5,000 / 1,136 |

Larger sizes are available upon request – contact the Hydro Thermal team for more information.

Related Literature

Maximize Your Process Potential

Don’t miss out on the benefits of ultra-precise, efficient, and reliable steam injection heating and cooking systems. Contact us today.