Hydroheater®/Jetcooker™

Pressure & Temperature

- Max Pressure – 300 PSIG / 20.7 Barg

- Max Temperature – 450°F / 232°C

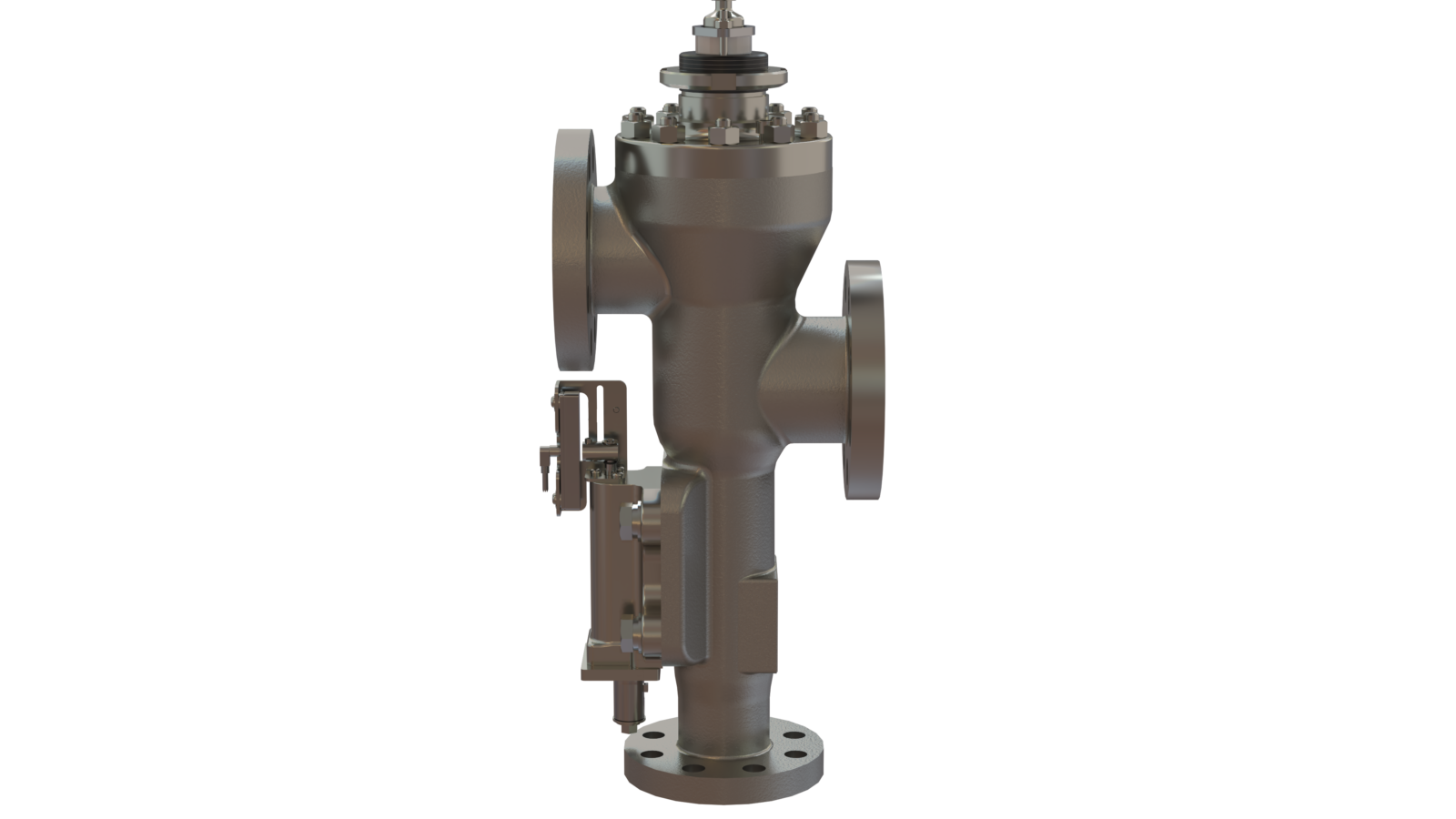

M-Series Hydroheater

- Max Pressure – 300 PSIG / 20.7 Barg

- Max Temperature – 450°F / 232°C

Flow Turndown

K-Series Hydroheater

- 3:1 Turndown Ratio (Water)

- 2:1 Turndown Ratio (Viscous Slurries)

M-Series Hydroheater

- 3:1 Turndown Ratio (Water)

- 2:1 Turndown Ratio (Viscous Slurries)

Connection Types

- ANSI Class 150 & Class 300

- DIN PN16, PN25, PN40

- Other custom connections available

Materials of Construction

- 316 Stainless Steel

- Other custom materials available

- Patented internal design allows for precise control of steam and turn-down adjustability

- Self-cleaning design eliminates scale build-up and product fouling

- Steam flow control creates consistent, instantaneous mixing and steam velocity while eliminating hammer and vibration

- Choked flow technology accurately meters steam for precise temperature control

- Precise temperature control (+/- 1 degree) helps you reach and hold your desired set point

- Uniform heating of water, liquids, and slurries

- Process flexibility and stability ensured through a detailed design and engineering process

- Starch Cooking

- Biofuels

- Anaerobic Digestion

- Starch Conversion

- General Water Heating

- Chemical

- Pharmaceuticals (Personal Care & Bio Tech

- Energy & Utilities (Oil & Gas)

- Starch to Sugar

- Paper & Pulp

- Renewable Fuel (Ethanol)

Other

- Mining (Processing Facilities)

- Metal

- Automotive

Sizing & Process Parameters

K-Series 2 1/2″-10″ / DN65-DN250

K610 | K611 | K612 | K613 | K614 | K615 | |

Steam Inlet | 2.5 in. / 63.5 mm. | 3.0 in. / 76.2 mm. | 3.0 in. / 76.2 mm. | 4.0 in. / 101.6 mm. | 6.0 in. / 152.4 mm. | 8.0 in. / 203.2 mm. |

Process Inlet | 2.5 in. / 63.5 mm. | 3.0 in. / 76.2 mm. | 3.0 in. / 76.2 mm. | 4.0 in. / 101.6 mm. | 6.0 in. / 152.4 mm. | 8.0 in. / 203.2 mm. |

Process Outlet | 2.0 in. / 50.8 mm. | 2.0 in. / 50.8 mm. | 2.5 in. / 63.5 mm. | 4.0 in. / 101.6 mm. | 6.0 in. / 152.4 mm. | 8.0 in. / 203.2 mm. |

Min. Flow (GPM/m3/hr) | 28.0 / 6.4 | 40.0 / 9.1 | 40.0 / 9.1 | 120.0 / 27.3 | 300 / 68.1 | 400.00 / 90.9 |

Max. Flow (GPM/m3/hr) | 174.0 / 39.5 | 402.0 / 91.3 | 402.0 / 91.3 | 750,0 / 170.3 | 1,800 / 408.8 | 2,500.00 / 567.8 |

Weight | 160 lbs. / 72.6 kg. | 297.0 lbs. / 134.7 kg. | 305.0 lbs. / 138.4 kg. | 447.0 lbs. / 202.8 kg. | 704.0 lbs. / 319.3 kg. | 934.0 lbs. / 423.7 kg. |

Larger sizes are available upon request – contact the Hydro Thermal team for more information.

Maximize Your Process Potential

Don’t miss out on the benefits of ultra-precise, efficient, and reliable steam injection heating and cooking systems. Contact us today.