Overview

Specialty proteins—such as those derived from plant sources, insect-based proteins, and innovative protein isolates and concentrates—are gaining traction in the food industry due to their versatility and health benefits. The production of these proteins requires precise heating solutions to maintain functionality, achieve desired textures, and meet food safety standards.

Direct Steam Injection heaters offer a highly efficient, controlled method for heating specialty proteins, ensuring quality, safety, and consistency at every production stage:

- Preserves protein functionality and nutrition by minimizing high-temperature exposure, maintaining amino acid profiles and bioavailability for specialty health applications

- Delivers smooth texture and solubility, enhancing appeal in beverages, supplements, and meat alternatives by preventing clumping and ensuring even consistency

- Ensures efficient pasteurization with on-demand, uniform heating, supporting regulatory compliance and consumer safety without compromising protein quality

- Boosts production speed with instant heating, supporting higher throughput and allowing producers to meet demand without sacrificing quality

- Reduces fouling by eliminating intermediary heating surfaces, simplifying cleaning, and reducing downtime in production

- Lowers operating costs with high thermal efficiency, reducing energy consumption and aligning with sustainability goals

- Enhances emulsification, creating stable mixtures for products like plant-based milks and protein drinks, ensuring well-dispersed proteins and fats

Hydron™

Hydron™ is the most precise, accurate and versatile Sanitary Hydroheater™. Its modular 3-A-certified design delivers optimal process flexibility and stability in an easy-to-use and maintain design. Reduce energy consumption and maintain product quality, consistency and conditions for your food & beverage processes.

- Volume capability: 1 up to 460 gpm [0.2 up to104.5 m³/hr]

Infuze™

Infuze™ heater is a compact and fully sanitary Hydroheater® that helps products achieve finished recipe results like pasteurization or blended emulsification and holds 3-A, EHEDG, and FDA certifications. Incorporated into our Silverline system, the Infuze revolutionizes heating in food and beverage processes.

- Volume capability: 3 up to 255 gpm [0.7 up to 57.9 m3/hr]

Learn More Request Quote

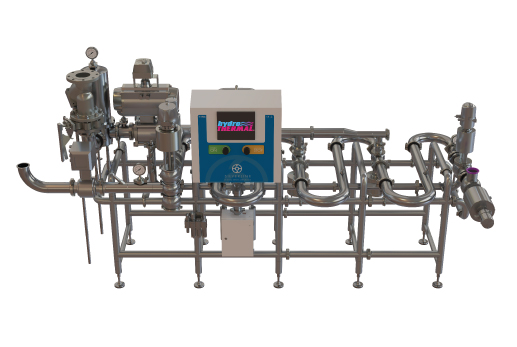

Silverline™

Silverline™ is a polished stainless-steel system engineered to replicate specified processing profiles, boasting 3-A certification and EHEDG, CE, and FDA requirements. This unit represents thousands of hours of engineering into a single, advanced machine – making it one of the most advanced food and beverage processing systems.

- Volume capability: 5 up to 200 gpm [1.1 up to 45 m3/hr]

EZ Heater®

EZ Heater® is an industry leader in hot water applications, featuring internal modulation and a self-cleaning ability. With on-demand hot water where you need it, EZ Heater is ideal for washing stations, Clean-in-Place (CIP) systems, and anywhere reliable hot water is needed.

- Volume capability: 2 up to 1,350 gpm [.5 up to 306 m3/hr]