Overview

In the meat processing industry, precise and efficient heating is critical for various applications, including scalding, cooking, sanitization, and rendering. Traditional heating systems like steam boilers or indirect heat exchangers often struggle to maintain consistent temperatures and require extensive maintenance, impacting production efficiency and product quality.

Direct Steam Injection heaters provide an advanced solution that delivers on-demand, precise, and uniform heating, meeting the unique demands of meat processing:

- Provides on-demand, consistent heating for scalding, ensuring efficient hair, feather, and skin removal while preserving meat quality

- Enhances energy efficiency with nearly 100% thermal efficiency, reducing energy consumption and operational costs for large-scale processing

- Improves sanitation and product safety by injecting high-temperature steam, sterilizing surfaces, and process liquids to reduce contamination risks

- Reduces maintenance needs and downtime with fewer moving parts and minimized scaling, allowing continuous operation in high-demand environments

- Ensures precise temperature control that prevents hot or cold spots for quality cooking and rendering, maintaining texture, flavor, and product consistency

- Increases throughput with fast heat transfer, reducing processing times and enabling facilities to meet production targets efficiently

- Features a compact, adaptable design for easy integration into existing systems, optimizing space for facilities looking to retrofit or upgrade

NOH™ (Non-Obstructing Heater)

Non-Obstructing Heater™ (NOH) is rugged enough to handle even the toughest abrasive materials, like sand and grit, to fibrous materials and large particulates. Its flow-through design protects against plugging, fouling, and pressure drops with its unrestricted flow.

- Volume capability: 30 up to 3,035 gpm [6.8 up to 689 m³/hr]

Solaris®

Solaris® heater offers a straight through design with low-shear flow, perfect for heavy slurries with medium consistency or higher solid contents. The diffuser injects steam across the entire cross-section to ensure thorough mixing and a uniform temperature even at a high volume and flow rate.

- Volume capability: 5 up to 25,000 gpm [1 up to 5,678 m³/hr]

Infuze™

Infuze™ heater is a compact and fully sanitary Hydroheater® that helps products achieve finished recipe results like pasteurization or blended emulsification and holds 3-A, EHEDG, and FDA certifications. Incorporated into our Silverline system, the Infuze revolutionizes heating in food and beverage processes.

- Volume capability: 3 up to 255 gpm [0.7 up to 57.9 m3/hr]

Learn More Request Quote

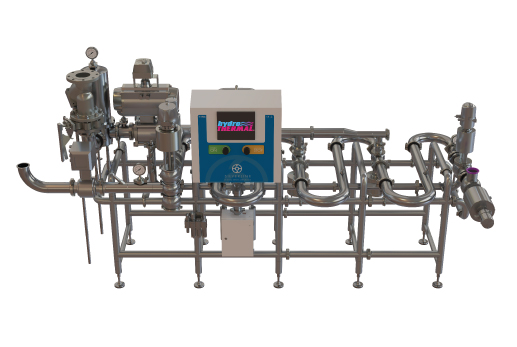

Silverline™

Silverline™ is a polished stainless-steel system engineered to replicate specified processing profiles, boasting 3-A certification and EHEDG, CE, and FDA requirements. This unit represents thousands of hours of engineering into a single, advanced machine – making it one of the most advanced food and beverage processing systems.

- Volume capability: 5 up to 200 gpm [1.1 up to 45 m3/hr]

Hydron™

Hydron™ is the most precise, accurate and versatile Sanitary Hydroheater™. Its modular 3-A-certified design delivers optimal process flexibility and stability in an easy-to-use and maintain design. Reduce energy consumption and maintain product quality, consistency and conditions for your food & beverage processes.

- Volume capability: 1 up to 460 gpm [0.2 up to104.5 m³/hr]

EZ Heater®

EZ Heater® is an industry leader in hot water applications, featuring internal modulation and a self-cleaning ability. With on-demand hot water where you need it, EZ Heater is ideal for washing stations, Clean-in-Place (CIP) systems, and anywhere reliable hot water is needed.

- Volume capability: 2 up to 1,350 gpm [.5 up to 306 m3/hr]