Overview

The processing of ice cream additives is a critical aspect of ice cream production, impacting texture, flavor, and overall product quality. Additives such as stabilizers, emulsifiers, flavorings, and colorings must be incorporated into the ice cream mix efficiently and consistently to achieve the desired characteristics.

Direct Steam Injection heaters offer several advantages over traditional heating methods in processing these additives, making them an ideal choice for modern ice cream production:

- Instantaneous heating speeds up lactose separation and improves production efficiency, enabling higher throughput with in-line processing

- Minimized exposure to high temperatures preserves texture, flavor, and nutrients of dairy by-products while preventing burn-on during production

- Reduced energy consumption through minimized heat loss, delivering cost savings, and supporting sustainability goals

- Space-saving design with low-maintenance requirements enhances production efficiency and reduces downtime

- Adaptable to various dairy by-products, ensuring efficient lactose separation across multiple streams with consistent results

- Advanced features like in-line heating and an air gap in the Hydron™ improve performance and streamline operations

Hydron™

Hydron™ is the most precise, accurate and versatile Sanitary Hydroheater™. Its modular 3-A-certified design delivers optimal process flexibility and stability in an easy-to-use and maintain design. Reduce energy consumption and maintain product quality, consistency and conditions for your food & beverage processes.

- Volume capability: 1 up to 460 gpm [0.2 up to104.5 m³/hr]

Infuze™

Infuze™ heater is a compact and fully sanitary Hydroheater® that helps products achieve finished recipe results like pasteurization or blended emulsification and holds 3-A, EHEDG, and FDA certifications. Incorporated into our Silverline system, the Infuze revolutionizes heating in food and beverage processes.

- Volume capability: 3 up to 255 gpm [0.7 up to 57.9 m3/hr]

Learn More Request Quote

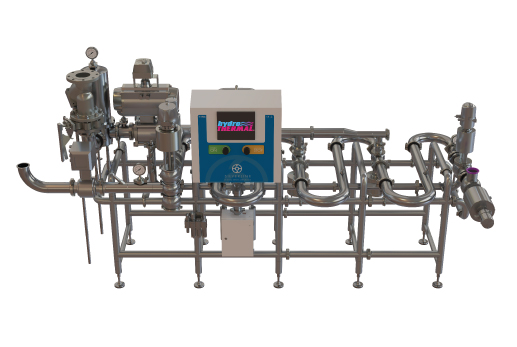

Silverline™

Silverline™ is a polished stainless-steel system engineered to replicate specified processing profiles, boasting 3-A certification and EHEDG, CE, and FDA requirements. This unit represents thousands of hours of engineering into a single, advanced machine – making it one of the most advanced food and beverage processing systems.

- Volume capability: 5 up to 200 gpm [1.1 up to 45 m3/hr]

EZ Heater®

EZ Heater® is an industry leader in hot water applications, featuring internal modulation and a self-cleaning ability. With on-demand hot water where you need it, EZ Heater is ideal for washing stations, Clean-in-Place (CIP) systems, and anywhere reliable hot water is needed.

- Volume capability: 2 up to 1,350 gpm [.5 up to 306 m3/hr]